I-CGSZ2242 Umshini Wokuhlela Kabili Wengilazi Esheshayo

I-CGSZ2242 Umshini Wokuhlela Kabili Wengilazi Esheshayo

DESCRIPTION

■Imigqa eqondile ekabili engaphansi kanye ne-arris yengilazi ingacutshungulwa ngesikhathi esisodwa ngokugaywa kahle, nokupholisha umoya.

■Isakhiwo se-All-in-one somshini kanye nebhokisi lesifunda lihle ekungangeni kwamanzi, ukonga isikhala futhi lilungele ukusebenza.Umzimba oyinhloko usebenzisa insimbi ekhonjiwe ngokwelashwa kwe-annealing.

■Kufakwe nomhlahlandlela womugqa omuhle kakhulu nama-screw mandrels aqinisekisa ukunemba kokucubungula.Ubakaki wesistimu eseceleni egudlukayo uyiklamo yohlaka luka-W, okwandisa ukunemba kokunyakaza kanye nezinga lokuzinza;futhi inganweba isikhathi sokuphila se-rack linear

■Idivayisi elungisiwe indawo yengezwe emshinini, oxazulula inkinga yokuchezuka kwengilazi encane, futhi ibone ukusebenza okukhaliphile kwemishini exhunyiwe lapho idlulisa ingilazi.

■Ukulawula kwe-PLC ngesikrini esithintwayo, ukulungiselelwa kwedatha kanye nesimo sokugaya ingilazi kungabonakala esikhungweni sokulawula.Ububanzi bokucubungula, ukujiya, nokuphakanyiswa kwama-arris angaphezulu kulungiswa ngokuzenzakalelayo.

■Ukupholishwa kwe-pneumatic okuthuthukisiwe kusebenzisa isitimela esinembayo esiphezulu somugqa ukuze siqondise futhi lesi sakhiwo singenza ukupholisha kuzinze futhi kuthembeke, kanye nokulondoloza isondo lokugaya ngempumelelo.

ISICELO

Ingilazi yokwakha

Ingilazi Yezimboni

Umnyango kanye newindi Glass

Ifenisha Glass

Ingilazi yomshini

UKUBEKA AMAsondo

| Ukujiya Kwengilazi | 3-25 mm |

| Ubuncane bosayizi Ocutshunguliwe | 350*350mm |

| Usayizi Ocutshunguliwe Omkhulu | 4200 mm |

| Isivinini Senqubo | 1-15m/min |

| Ukuphakama Kokusebenza | 920 mm |

| Amandla Aphelele | 70kw |

ISAKHIWO EZINGXENYE

01 KunengqondoUkwakheka kwamasondo

Yamukela uhlobo lwemoto oludumile “ABB” , kanye nesakhiwo esiphusile samasondo ukuze wenze ukusebenza kahle onqenqemeni lwengilazi.Imigqa eqondile ekabili engaphansi kanye ne-arris yengilazi ingacutshungulwa ngesikhathi esisodwa ngokugaywa kahle, nokupholisha umoya.

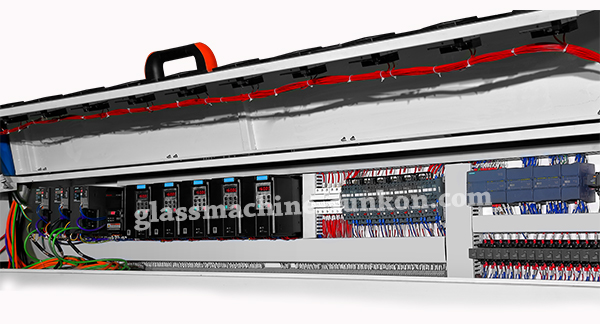

02 Ibhokisi lesekhethi elihlelekile

Yamukela izingxenye zikagesi ze-Schneider kanye ne-Siemens PLC.Isakhiwo se-All-in-one somshini kanye nebhokisi lesifunda lihle ekungangeni kwamanzi, ukonga isikhala futhi lilungele ukusebenza.

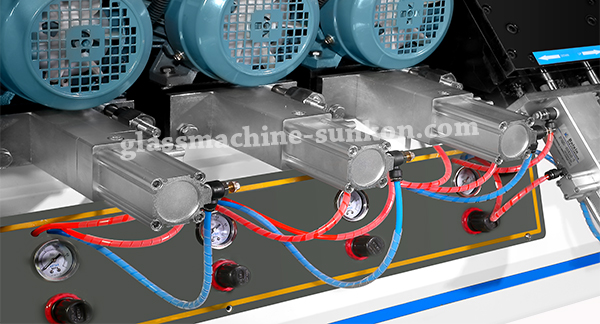

03 Ukupholisha umoya

Wonke amasondo okupholisha asebenzisa ukupholishwa kwe-pneumatic, kanye tIkhanda elipholishayo lingena liphuma ngomoya ngesikhathi esifanayo, lifakwe inqola yemoto enembe kakhulu, umphumela wokupholisha uqinisekisiwe

04 Isilawuli esivulekile sobubanzi bokucubungula ingilazi

I-Siemens servo motor ilungisa ukuvulwa nokuvalwa komshini ukuze uqiniseke ukuthi usebenza kahle ngisho nangesivinini esikhulu.

05 Extra cutting quantity thola idivayisi

Lapho onqenqemeni extra wengilazi ezayo thintaes le divayisi, kuzokwenzadlula isignali ku-PLC futhi umshini uzokwaziswa ku yehlisa ijubane for this umphetho owengeziwe.Khona-ke ingilazi yokugaya kanye nekhwalithi yokupholisha izoba ngcono kakhulu.

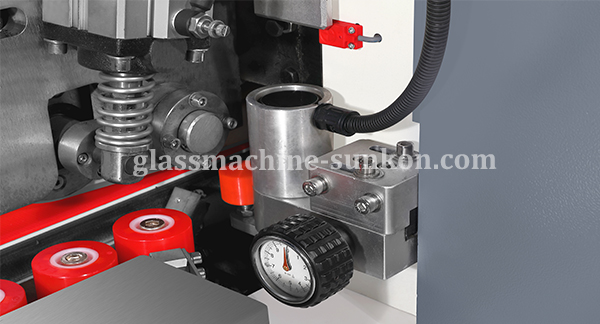

06 Idivayisi yokulungisa ingcindezi eseceleni

Isakhiwo okokufaka sinedivayisi yokulungisa ingcindezi eseceleni, okulula ukuyilungisa nokuyilungisa.

IKHASI LEKHASIMENDE

-600x600.jpg)